TubeWaySolar

Developmental study of a pneumatic path-guided transportation system

by Michael Thalhammer

Short version to a modern public transport system

It was during the millennium when the mental connection between a pneumatic tube and a modern traffic system flashed into my mind.

TubeWaySolar was born.

TubeWay could be an answer to many challenges of our time: on the one hand to preserve mobility in the long term and on the other hand, to avoid a further burden on the environment with CO², noise and stench.

It soon became clear to me that the drive should exclusively come from the sun. On the tubes large-scale were applied photovoltaic films generate electricity from sunlight.

TubeWay glides fastly, quietly and emission-free in glass tubes - and has the capacity of a 6-lane highway.

Speeds up to 300 km / h can be achieved.

The route runs on elegant highways and offers a clear view from an average height of 7 meters.

TubeWay claims only little ground. Naturally grown habitats are preserved for humans, animals and for agricultural use as well.

With TubeWay persons put also goods can be moved.

About 100 people or 10 tons of freight can be accommodated in one cabin.

Safety is top priority at TubeWay: the entire route network is controlled and monitored via computer-aided control centers.

TubeWay helps to advance energy and mobility.

My big concern is to protect our unique planet and to preserve our common living environment.

www.tubewaysolar.at - I am pleased, that you´re enjoyed this video, even more pleased if you´ll share it with your friends and acquaintances.

In the long term, we will still need our fossil

reserves for many things. But our mineral oil is far too valuable for climate-damaging exhaust fumes and road asphalt. our mineral oil is far too valuable!

TubeWay's have the effect that urban traffic areas - as a result of reduced traffic volumes - are transformed back into green and quiet spaces that can be used by residents.

The change to renewables can be made with all-round benefits. It should and must enable future generations to sustain their lives!

Now follows the smaller network TW-Sit-in-surf (TW-SiS) designed for regional transport; this is followed by the TW-Inter-City (TW-IC network) - and then the urban TW supply and disposal network TW-40 (cm). Their technical system safety is also discussed.

See also: http://www.youtube.com/watch?v=19YDKukm2vc&t=18s

- the Video >> TubeWaySolar - for a clean future.

TubeWaySolar

Part 1

TubeWay in the sit-in-surf version

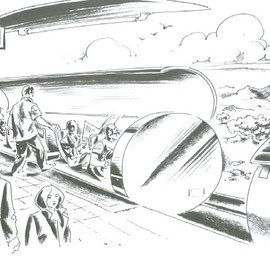

Illustrated here is the TW sit-in-surf (TW-SiS network) with an internal diameter of about 1.9 m and its approx. 20 m long cabins:

Its application would be of great benefit to urban areas and as a regional transport network.

In the inner city, the routes run just above the buildings and partly rest on them.

Sit-in-surf offers, with lateral access and egress to the 3-bench seating rows, a high transport density. With ~ 75 passengers each, in short intervals, which is particularly beneficial for working people and inner-city traffic, it forms a forward-looking, superordinate transport network.

The sandwich spiral sheet metal tube routes used here would be well able to cope with the stresses of rural terrain, as well as various climatic and seasonal conditions. The length of the pipe modules here would be about 20 metres. The distance of the pier arches is ~ 100 metres.

TW as a sit-in-surf is easy to launch anywhere; and for this, only about one million euros per track kilometre are to be budgeted. Pre-development costs are also only about one third of the costs of a TW-IC line.

TW-SiS travels in urban areas at a maximum of 85 km/h; in regional areas it reaches up to 190 km/h; the large TW/IC, on the other hand, "flies" over the countryside at up to ~ 310 km/h, roughly estimated.

The cargo capacity in a sit-in-surf capsule would be about 16 pallets with up to ~ 6 tonnes of cargo. In the "SiS", too, users can be timed via the ticket or the freight fare. Passengers as well as goods glide in their own cabins or capsules.

About 3 m of the interior space is dedicated to the space required for prams and wheelchairs. There are no on-board toilets in this short-haul network, but larger stations are provided with a toilet. Although this short-haul network does not offer a view to the outside, it may be possible to consider discreet, quiet music here.

All suggested dimensions are concept-descriptive estimates.

How does TubeWay work technically ?

Basically, two-directional routes are envisaged, which are guided parallel to each other with flexible spacers.

Supporting cables, tube composite and pier arches ensure the necessary safety for traffic on such elevated tracks.

The bridge statics support a bi-directional section, the sliding units and the media line at a height of ~ 7 metres. One arch support carries approx. 30 tonnes of track weight plus ~ 13 tonnes of traffic loads. The slender track pier arches hold the TW track on its course using vibration-free tension cable technology.

Cabins or cargo capsules glide in a permanent air stream to their pre-coded destinations.

They glide over a 1 m wide, mirror-smooth stainless steel trough bonded with VHB tape from 3M Scotch.

The soles of the cabs carry sliding rings made of indestructible Teflon**. These rings (5 x 3 mm, 50 mm diameter) embedded in a cork bed support layer bear ~ 15 kg each at full load.

All 260 sliding rings together occupy only 0.5 m² of the 18 m² sole surface. They provide dynamic permanent contact with the high-gloss channel.

A 2 mm hard plastic cable runs into the centre of each Teflon ring. These provide a compressed air supply via an electric on-board compressor, as a glide-optimising air cushion. These supply lines are also embedded in the cork sole.

This compressed air input lifts the cabins out of dry sliding friction and into permanent "micro-floating".

The compressor takes its air from behind the cabin and loses it again to the rear via the Teflon rings.

The coefficient of sliding friction is thus probably in the extremely low range of ~ 0.01. The on-board compressor would also be well soundproofed.

* The pipe diameter is only an average recommendation, in whose dimension the most common general cargo sizes find their transport volume. This diameter does not accommodate large or too heavy dangerous goods or those that cannot be transported by TW. These will continue to be transported by rail and freight.

The cantilever support arches with their bolted bases carry the two draw frames in direct ballast. The arch centre holds the tensioning cables on which the track modules are suspended. // The tensioning ropes are ultra-light fibre ropes from Dyneema, Teufelberger or Trowis. They are stronger than steel, UV-stable, light, water-repellent and inexpensive.

** Teflon (PTFE - polytetraflourethylene) is - as the most inert plastic - heat-resistant, abrasion-resistant and pressure-resistant. Sliding and friction values are both close to zero. Even the extremely heavy sarcophagus for the Chernobil reactor could be moved using Teflon plates. // This extremely durable material is - in relation to rail wheels or rubber tyres - far more cost-effective.

Now for the propulsion:

E-locomotive propulsion pods act as all-propelling pneumatic drives at intervals of 3 to 7 km.

The complex laminar, turbulent and/or boundary layer separating flows that occur here naturally require highly professional flow expertise for the overall planning of the hermetically sealed

of the hermetic pneumatic ducting system.

In order to make the airflow hermetic, non-contact felt seals are applied to the outer wall of the cabin, towards the pipe. As multi-chamber seals, their profile forms rotating, fully sealing air rollers. The overpressure dynamics in motion as air rollers prevent any flow of the propulsion medium past the hermetic seal, in particular the direction of rotation of the airrollers,

The electric locomotives are also surrounded by a series of these seals.

Running on eight Kevlar-reinforced drive wheels, these locomotives transmit their relatively economical bull power of just ~ 3 kWh/km to the front and rear deck shields of the cabs. The propulsive force reaches the front and rear sliding units in dual suction/pressure power.

The articulated, approx. 2.6-metre-long electric locomotives each follow their logistical work dictation and, if necessary, switch to the opposite lane via reversing curves or into stand-by loops.

With the air flow dynamics and the gentle force of suction and pressure, each E-locomotive pulls and pushes up to ~ 35 units along with it. This imparts a high sliding smoothness to the entire non-stop system.

In fact, the lateral flow to the pipe wall is far less than, for example, when water flows through a garden hose.

Speed changes occur in barely noticeable, smooth transitions and happen like this: The electric locomotives are switched to the respective dedicated speed by sensor, directly from the track section.

In order to achieve more or less distance between the units at the point of the speed change, the air produced as surplus during deceleration is diverted - by means of a pipe bend connection - to the acceleration side vis-a-vis. The energy from deceleration is thus introduced vis-a-vis as pneumatically loss-free thrust.

In addition, "chimneys" distributed along the track enable air volume control to be diverted in and out.

To the solar PV films:

By covering the tube routes with 2-metre-wide PV thin-film foil*, we get an enormous electricity gain all year round. On north-south routes, the PV rows that can be moved there can be automatically tilted according to the E-W course of the sun (lateral film shifting).

PV-foils provide long-lasting use and have a productive input of solar power even in diffuse daylight.

The PV cells keep the tracks shaded on hot days. Surplus electricity generated during the day is fed into the grid to provide night-time mobility**. Summer surpluses are fed to consumers close to the track.

Every year, the PV cells and pipes are preserved with a nano-layer for a self-cleaning lotus beading effect.

In snow load regions, an intermittent hot blower cuts through the snow cover at the top of the modules. In this way, the snow on the nano-coating and due to the reflective heat of the dark PV surface easily slides off to both sides.

* Currently, suppliers such as: AltaDevices, Flisom, Heliatek, Alwitra-Evalon-cSi, FirstSolar, Nanosolar or Solaronix with their AgAs, OLED, DSSC, PSC or CIGS thin-film cells have a good price-performance ratio. They can be cut to size, are lightweight, self-adhesive, inexpensive to manufacture, easy to recycle and high-yield even in dim daylight.

______________________

All locomotives and cabs have articulated joints in the floor that are suitable for curves.

Empty, the aluminium cabins weigh approx. 2000 kg and offer comfortable seating in rows with three seats each.

Luggage can be stowed under the seat, and a folding table and USB port provide modern travel comfort.

The interior is optimally made of natural lightweight materials (e.g. bamboo).

The internal electrical supply is received by means of a contact brush from a flat conductor laid in the tube top. This contact brush is trailed by a spring-loaded rod at the rear.

An air conditioning system controls the fresh air supply and the internal temperature of the fresh air inlet located in the rear top. The filtered cabin air flows through the driving units - in dosed normal pressure - from the rear to the front.

Space for prams and wheelchairs is provided in the boarding area; these passengers may also alight there.

Public stations are added to the main dynamic flow as a bypass. At the stopping point (usually via existing transport nodes), two passenger lifts transport the boarding and alighting passengers to the track or ground level.

Separate entrances and exits create circular passenger flows. Lifts and cabin arrivals run just in time. These steps are monitored by cameras and the doors are then automatically closed for departure.

The arrival of the cabins in the parallel-separated station bypass tube is done by means of hydraulic leverage. The energy for the initial push in the station area comes to ~ 70 % from the regenerated braking energy of the arriving units; they transfer this power to flywheel dynamos embedded in the floor.

At each passenger station (as well as each goods loading point), the gross weight of a sliding unit is weighed. Also, the exact starting torque is calculated for the insertion into the permanent flow of the main pipe; and the necessary power input is transmitted to the e-board compressor.

Already during start-up, the described hermetically sealing air vortex barrier is created.

At the end of the station bypass (as at the entrance) there is a sluice gate. From this point on, each cabin is in the logistical control of the main stream; and, from 40 km/h before, is now carried along at 65 km/h. These sluice gates operate as nimble double-wing sliding doors.

At junctions, the pipe splits; and begins with the channel rocker bifurcated as a switch. The target of the cabin orients the turnout, while the other pipe way gate closes automatically. A large air inlet is fitted to each of the pipes at the branch. These provide the current volume requirement of their route.

At feeders, a controlled zip principle takes effect. Here, too much air is discharged to the outside. At these, there are also turning or waiting loops for the electric locomotive operation concerted by the control centre.

In curves, the load weight follows its unhindered momentum. The slide troughs are wider there. Due to the freedom of the centre of gravity, the curves can hardly be felt at any speed. Goods capsules also reach their destination with unshifted loads.

Five to twenty-five units per kilometre of track are the system-energy ideal in TubeWay.

Michael Walde, Dip.Ing. for High Vacuum and Thin Film Application Technology

wrote to me on 18.11.2017 via LinkedIn:

I think the idea is very good. Did the calculation once with thin film solar surfaces on the transport pipes (roughly) and came to the amazing conclusion that assuming a distance of 400 km with a space utilisation of 50% on the pipe diameter, immense amounts of energy would be available: at least about 1.6 million square meters for solar use.

With an annual solar mean of 1200 kWh / m² and 15% efficiency, 105 W / m², i.e. 168 kW, are combined on the calculated area of radiant power. An electric locomotive needs about 15 kWh / km [DB AG]. With a travel time of 3 hours and a distance of 400 km, the average power per locomotive would be 1500 kW.

The amount of energy generated would therefore be sufficient to run a few locomotives on the fictitious route; the tubular locomotives should also run even more efficiently than a conventional electric locomotive. Interesting, even if my assumed values reflect the facts in a very simplified way.

* GaAs are Galium-Arsenic Cells and CIGS Cells and cheaper than the stiff, heavy silicon panels. They utilise a broader light spectrum, and therefore have nearly the same power output as silicon cells, which only produce electricity in direct sunlight, even in hazy weather. OLED and CIGIS films are lightweight, have a sufficiently long service life and do not pose a waste problem.

** On the problem of a generally growing need for storage of electricity surpluses, there is the approach of e.g. ADELE, which is a compressed air storage power plant, or the www.Lageenergiespeicher.de by Prof. Eduard Heindl.

*** In GEO 6/2003 there is a detailed report on the possible uses of glass today: Modern architecture builds large buildings with delicate but highly resilient glass tubular girders. The test centre of the building and approval authority could not make the test object collapse with all the force of the hydraulic press. Even under fire with steel bolts, the tube piece held up for days.

Physical facts about TubeWay:

The estimation of the energy required to generate air flow can be determined with the calculation "tube cross-sectional area times velocity times pressure expenditure". For each glider, a value between Hagen-Poiseull's equation and Reynolds number applies.

If a pressure of only one tenth of an atmosphere (= 0.1 kp/cm² or a 10 cm high water column) acts on our cabin tail with a circular area of 3.2 m², a force in the direction of movement of 3200 kp already acts on the cabin; this would accelerate a weight of 3 tons to over 75 km/h in 5 seconds!

Since air has a low density compared to water, a small as well as a large pipe diameter in physically favourable flow is to be considered - in comparison with small as well as large ships. Therefore, the lateral flow to the pipe wall is proportionally far less than, for example, the flow of water in a garden hose.

Technical conclusion:

# Unlike magnetic levitation trains, TubeWaySolar

does not pollute either the passengers or the neighbours close to the track with the alarming micro-test load radiation* of powerful magnets.

# CO2 emissions, noise, friction losses and the use of fossil fuels are completely eliminated with "TW".

# TubeWaySolar bypasses the air conditions that prevail outdoors, where resistance increases by the square as speed increases

# TubeWaySolar easily overcomes heights, crosses rivers and valleys with ease. This hermetic system is almost completely spared the effort normally required for uphill travel by the

subsequent downhill gliding of the same loads.

# TW bypasses outdoor air conditions where resistance increases reciprocally with speed.

# TWs use their tube-internal air as a positive driving force

# The system replaces heavy bogies and equally heavy track substance

# The overall system is highly wear-resistant and low-friction

# The material basis and the solid manufacturing process make the low-maintenance operating lines made of used glass fully profitable

# The fast tube air works with only ~ 0.4 bar difference between suction and pressure side

# TW systems offer the ideal complement to other forms of transport and

# they are capable of gradually replacing climate-polluting traffic

# TW carries its own PV foils, for solar-autonomous energy supply

# This hermetic system is almost completely spared the effort normally required for uphill travel by the subsequent downhill gliding of the same loads

# TW overcomes heights with ease, crosses rivers and valleys with ease and

# it never needs snow chains TubeWay, of course, offers technical solutions to the following problems of today's traffic:

# high costs of maintaining roads, motorways and the mostly empty railway tracks

# emissions of environmental toxins and noise; sickening effects

# waste of valuable fossil and other resources

# high and short-lived material costs, and

# high land requirements for transport

# accident frequency and consequential damage

# Time lost due to traffic jams and permanent stress.

TubeWay's therefore offer the solution for the climate-necessary traffic turnaround!

How safe are TubeWay operations and their structure?

The TW networks are - as is usual for railway networks - subject to nationally separated territorial authorities.

Nevertheless, uniform standards are needed - e.g. for network maintenance and servicing. Thus, all TW networks should also have a globally uniform standard diameter.

As a means of transport of the future, TubeWay must be managed and monitored sensitively.

With new high standards for safe transport operation, it relies on radio and fibre optic telematics as well as on highly trained support and technical staff in all area structures.

All system functions are secured by mutually controlling computer systems and emergency power generators.

Only passengers with personal, active TW value cards can enter the network and use it within the booked routes.

Each tube tunnel is secured against access in such a way that only access and egress to the sliding cabins is possible. Each platform has recording videos and at least one supervisor.

Each cabin is equipped with a direct intercom system, fire extinguishing blankets and is monitored by camera. For system safety, the lines are equipped with pressure anomaly detection at points and have external sound and motion detectors and possibly night vision equipment at sensitive points.

The defined high-security programmes in the logistics centre operate under constant supervision. The highest decision-making authority remains with human system supervisors.

Any necessary slowing down of a section is initiated in the regional centre concerned by localised diversions. In the event of a stop, with the need to disembark, instructions are given from the respective control centre.

Repair or rescue teams are then immediately instructed and proceed to the incident appropriately equipped.

In the event of an emergency, the front and rear sides of the cabins have open escape doors, and at each pillar arch the track offers an emergency access or exit plus emergency descent (via cross-adjustable ladder rungs).

If the braking command for a section of track comes into effect, then a re-routing system (via reversing loops, a station or a parking loop) avoids that section. Units behind a handicap zone simply leave it; but those immediately in front are stopped and pneumatically brought back to the last switch. The transports in the overall network thus remain unaffected.

The specifications of the TW technology do not allow for a ramp-up. Ultimately, a highly compressed air cushion via the sliding capsule seals would result in a damped braking distance. In addition, the units and individual electric locomotives can be braked via the control centre.

The transversely movable sleeve O-rings between the pipe modules, provide the operating lines with favourable fault clearance and recovery possibilities even in the event of floods, storms or medium earthquakes.

The TW pillar arches, which are close to the ground traffic, must be structurally capable of withstanding any severe impact and will be rebuilt as appropriate.

Passenger traffic is limited to 6h to 22h. The day/night area is kept unattractive to each other through high time-tariff differences.

Dangerous goods will continue to be entrusted to road freight and the tried-and-tested rail park-and-rail.

All TW components are replaced with new ones at fixed intervals.

The reliability of the entire system could be as high as in air traffic.

Administration at TubeWay

For quick booking, network customers tap the destination on the interactive touchscreen network map at the terminal portal and make the transaction with the credit-based TW Card.

The TW-Card and its identity to the cardholder are carefully checked. Once they have reached their destination, the distance travelled is recorded electronically.

The transport of the nightly cargo is booked via telephone, fax or internet. The sliding capsules used are charged according to distance kilometres and weight via a user account.

The freight agency offers bulk, liquid, commodity and refrigerated capsules. It manages these and also carries out the relevant loading logistics.

A transport cabin offers - in the TW-SiS or TW-IC network - 6 to 13 tonnes payload or loading capacity for 16 to 22 EU pallets. All cabins can be emptied via Kant; sorting loading grabs are used for loading and unloading. This means that freight can be shifted efficiently in terms of transport logistics.

Hauliers, ports and factories can purchase or rent their own access tubes from the operator.

This kind of favourable transport leads to network expansions and brings about correspondingly adapted loading terminals.

The night-to-day user changeover can be done in about half an hour, transforming transport capsules into cleaned cabins, complete with bench seat installation. At night, the forwarding services, such as sorting, loading and delivery to the destinations, were done. This split >cab and capsule< saves a huge garage park and even more rush-hour work.

The largely private haulage business cooperates with TW network logistics in terms of time and participates via the usage tariffs. The TW network operator, on the other hand, is responsible for public passenger transport.

Part 2

The TubeWay-IC (InterCity)

The TW-IC is intended as a long-distance network linking large cities, so of course much more has to be calculated per construction kilometre. It uses the same technology as the TW-SiS.

The track consists of approx. 17-metre-long sandwich tube modules made of robust safety hollow chamber glass with an inner diameter of about 2.7 metres. These lined-up pipe modules (each weighing approx. 7.5 t) are joined together by sliding sleeves and O-ring seals and are also supported on slender track pier arches and by vibration-free tension cable technology.

Here, too, the bridge statics support the bi-directional section, the sliding units and the media line at a height of ~ 7 metres. Here, however, at a pier arch distance of 50 metres, approx. 50 tonnes of line weight plus an average of 20 tonnes of travelling loads per arch support have to be carried.

The relatively low loads bridge greater distances than conventionally concreted traffic carriers would allow.

In sensitive natural areas, the roadway is carefully extended with only half-length modules (delivered by cargo helicopter; they hold the respective pipe module in suspension for rapid jointing on site).

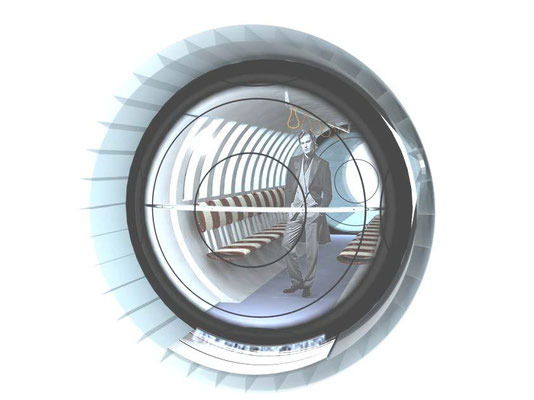

Up to 110 people per cabin (or 13 t cargo transport capsules) glide in a permanent stream of air to their pre-coded destinations. Side windows open up a panoramic high-altitude view.

The 26 m long cabins glide over a 1 m wide, mirror-smooth stainless steel trough bonded with VHB tape from 3M Scotch.

The soles of the cabins have embedded sliding rings made of indestructible Teflon**. These rings (5 x 3 mm, 50 mm diameter), embedded in a cork sole, each bear 20 kg at full load.

All 500 sliding rings together occupy only 1 m² of the 26 m² sole surface. They provide dynamic permanent contact with the high-gloss channel and are pressed into milled fitting grooves in the 12 mm thick cork bed base layer.

The seats are arranged here like in a coach. If required, there are about 20 standing places in the central aisle. An on-board toilet is located near the exit.

The TW-IC sandwich tube modules can be constructed roughly as follows:

The tough molten glass falls from a high tank through the sandwich profile nozzle.

Kurfen tubes also flow vertically out of the toughened melting nozzle. The latter are bent hot and also hardened in nitrate chlorite. Then the modules are sheathed, in addition with wire mesh and another layer of glass, and result as a double wall with longitudinal webs, light, highly stable VSG modules.

With such HiTec material, the strength of the tubular parts should even exceed the load-bearing value of steel/concrete***.

Waste glass is predominantly used in the process. There is sufficient collected waste glass for a TubeWay expansion.

Part3

The urban supply and disposal network TW 40

... with a diameter of 40 cm is sufficient, travels at around 35 km / h. Each 85 cm long capsule allows 20 kg of material to be conveyed; and in principle they glide to their destination using the same transport technology as the large TWs. A flex joint also ensures good manoeuvrability in tight curves.

This urban supply and disposal network (TW-40) would be of great use within our conurbations - e.g. for ordered shopping, the official gazette, food delivery, postal and parcel services, waste disposal, etc. - would be of great benefit in general.

Businesses as well as private individuals could be connected to the 40 cm network as optional subscribers - as with district heating.

It would be laid in the pavements and high up into the buildings. The municipal operator would deliver the appropriate capsules to the customer after each order.

Part 4

What are the business aspects and opportunities

of TubeWaySolar?

TWS mobility requires some upfront investment and carefully planned implementation steps, but once established, investors and operators could earn consistently secure profits from TubeWay. A variety of business sectors would emerge in parallel.

There are hardly any really reliable figures for large-scale projects, and I can't offer any here - however:

The technical MVP pre-development can be created - with little financial risk - via the small 190 cm net or the 40 cm net.

These initial networks generate the large IC network in a step-by-step financing plan.

In terms of legal form, it would be conceivable, for example, for the pipe routes to be nationally owned; the solar energy output could come from a joint-stock company, and the vehicle fleet could be under public administration. So several mixed forms are possible here.

TubeWay-Mobility is able to revitalise essential segments of our market and working world. The result is a win-win situation for customers, operators and our environment.

Competences from science, investment, EU infrastructure planning, municipalities, environmental groups and the corresponding industries have been addressed.

What is needed now is the appropriate capital consortium with affinity to politics and big industry.

The special TW technology that makes financing plausible

Railway tracks and motorway routes take up an enormous amount of ground space.

In the case of TW, only about 250 m² of support base annual rent can be calculated per kilometre of track - the capacity of a TW two-directional track would be equivalent to that of a four-lane motorway.

Road maintenance, winter services, traffic jams and accidents lead to considerable costs that burden the national economy! TW is weatherproof and rarely needs costly maintenance.

With the use of recessed base foundations, a track can be removed again without a trace and easily "like a roller coaster" and can be used elsewhere (2).

Nowadays, technical implementations can be created very quickly and also cheaply: a dozen specialist teams as well as a dozen core area companies offer financiers a manageable cost framework.

With the 2 or 3 metre wide PV foil coverings, solar power can be generated on the TW overall sections in quantities far in excess of the current demand. The surplus electricity generated during the day can be used as night-time electricity after being fed into the grid.

In addition, further surpluses would be competitively offered to consumers close to the line. With regard to the problem of a generally growing need for storage of electricity surpluses, compressed air storage power plants such as ADELE are a very viable alternative to large-scale battery plants. Prof. Dr. Ed. Heindl has also worked out a sensible and quite feasible solution of a >www.lageenergiespeicher.de<.

(1) Railway lines cost on average about 27 million euros per kilometre. For a motorway construction, even up to 70 million euros per kilometre have to be spent. These costs do not even include the respective land acquisition prices. In addition, the kilometres of motorway construction consume ~ 30,000 tonnes of sand, which is already rare and therefore expensive.

In a rough estimate, with a mature production structure, the TW/IC expansion should settle at well below the expansion costs of a railway line.

(2) Is TubeWay recyclable? TubeWay tube modules as well as tube cabins can be used for several years beyond their temporary use as a track structure, before their final recycling, for living quarters, etc.

As technically adapted and thermally insulated units, they could be built over and extended, e.g. with a transparent foil tunnel. The living feeling would remain close to the surrounding natural space.

Does TubeWay have realistic chances?

Not a single drop of spent fuel ever becomes available crude oil again! Fluctuating costs and import volumes keep the whole of Europe dependent.

Oil crises and rising energy costs do not affect this system or even make it grow indirectly. In particular, the CO2 increase in climate heating is now putting pressure on us to act!

The high-capacity transmission line does not have to fear the usual objections of affected landowners. No land will be divided or agriculturally restricted. TubeWay glides over fields, forests and pastures - visually discreet as well as emission-free and noise-free.

Sustainable energy technologies are already experiencing high growth rates. They promote employment, energy mix, social security and monetary circulation.

Market - Competitor - Strategy

Overall, we need to develop a sustainable solution for our future needs for general mobility!

Well planned, even a prototype route could be profitable and established. Because of its ecologically relevant, gentle and connectable technology, a broad customer identification with this modern form of mobility would quickly emerge.

After its construction, TubeWay does not depend on permanent public funding.

On the basis of pneumatic solar operation, TW passenger and freight transport can glide along in a "micro-float" that is unrivalled in terms of price and technology.

Business advantages with TWS:

# Reliability in terms of departure and arrival times for deliveries as well as passenger transport.

# Already one airport feeder route can act as a seed for growing TW networks

# 100 % solar, i.e. fuel-free and resource-saving eco-market advantage

# High acceptance - sympathy factor - low resistance in neighbouring areas

# Areas that implement TW can enjoy considerable advantages in the future

# Enormous savings potential compared to traditional transport

# Good ratio of investment, amortisation and profit

# Relatively low costs for operation and maintenance

# High prestige value, high safety standards

Should future transport be solar?

With TubeWaySolar as a broad-based transport system, we can prolong the preservation of the precious resources oil / natural gas by a lot. Even for an ecological future, we still need our crude oil for many applications that we do not yet know about today.

Our mineral oil is far too valuable for climate-damaging exhaust fumes and road asphalt!

Hydrogen always has to be pre-produced with electricity by way of expensive water splitting. Other options are not the best in terms of energy either.

TW reduces oil imports, climate-damaging pollutant levels, noise and traffic accidents.

TubeWay helps to reduce the burden of fossil electricity or the danger of nuclear electricity.

The shift to renewables can be made for the common good. After all, it should and must enable the life of our descendants. For our biosphere is in fact in global danger!

Comparisons with the state of the art

An overview of alternative and innovative forms of mobility and drive technologies can be found in the links :

http://faculty.washington.edu/jbs/itrans/list of 100+ systems > tubeway and www.buch-der-synergy.de

There you will find a collection of mobility approaches from all over the world, some of which have already been implemented. TubeWay is also evident in these.

TW can be developed in the style of the tube post, which has proven itself for 160 years. TW transports passengers as well as goods by means of the all-moving solar-electric internal drive.

TubeWay wants to avoid linear motors in magnet-induced track equipment - for reasons of unresolved compatibility issues with their high microtesla use, limited availability of magnetic material, weight reasons of the tracks and their "pods" and noise generation.

We are in a lively discussion process in which suitable alternatives are being sought with responsibility for people and nature. TubeWay may stand for the decision for technically simple, ecological mobility; and due to the worldwide scarcity of resources and energy, the need for rapid alternative solutions in the public transport sector is growing.

Historical background:

The original vacuum tube transport system was proposed by George Medhurst as early as 1799. Michael Verne, son of Jules, improved it to pneumatic tube transport in 1888. In 1904, Robert Goddard described a Vactrain Maglev; and soon after, an underground and purely pneumatic test track, paid for by a banker, was already carrying people in New York - but this was not extended.

Does TubeWay still have an upcycling use at the end?

Yes, after their performance as cabins and tube modules, they still serve as:

# green cultivation glasshouse tunnels

# converted living spaces

# housing estates staggered into pyramids

# as storage volumes

# to weather-protected cycle tracks and many more.

+ + +

Letter reference from the :

Vienna Environmental Protection Department - MA22 14.02.2013.

Dear Mr. Thalhammer

Your TubeWay appears to be a modern, sustainable, ecological and thus promising mobility solution. With "TubeWay solar", new urban development/expansion areas could be connected to the existing transport network without having to compete with the currently available public transport, or demand-driven cross-connections could be created in particularly sensitive zones.

If the results are positive, it would be quite realistic to implement the system, initially on test routes, to gain practical experience.

Since Austria is known worldwide for technical innovations, we see good chances for your idea to be implemented, especially in times of energy price uncertainty.

In this context, we would like to refer to the development bank (AWS) as well as EU funding programmes, which in your case could provide financial support for the in-depth studies that are necessary in any case.

We wish you every success in implementing your mobility concept, which is already close to reality.

Yours sincerely, Günter Rössler

Vienna Department of Environmental Protection - MA 22

Department: Traffic, Noise and Geodata

A- 1200 Vienna, Dresdner Straße 45

+ + +

I expect that the TWS implementers will not risk anything with BIT and the like. Coins, so that all investors find a real security regarding their participation!!!

I also warn against the use of a TWS expansion, purely for the conventional purpose of further transporting those goods and resources which are also due to our future generations!

It is necessary to encourage high finance and big industry to change to sustainability and the preservation of our globally common foundations. Let us actively take up this challenge!

Just as our heart manages to supply each of our body cells with life energy, we should be able to create new solar arteries of transport that connect us and enable us to continue

our universal mobility.

~ ~ ~ ~ ~ ~ ~

Whether Elon Musk's Hyperloop will result in a broadly feasible general solution to our future need for general mobility remains to be seen. Hyperloop-One, Virgin Hyperloop and HTT have been franchising for years with ever new Maglev success stories in technically vague 3D short videos.

This and more is well traced in www.buch-der-synergie.de under "Hyperloop".

Conclusion:

The World Health Organisation (WHO) is of the opinion that it is not yet possible to properly assess the health effects of micro-tesla radiation.

The environmental authority in Changsha states that the planned light rail will have electromagnetic radiation with a field strength of 1.6 microtesla. This is far less than the risk limit for humans of 100 microtesla, which has been in force in China since 1998.

Opponents, however, point to the example of Switzerland, where the risk limit is only 0.2 microtesla.

The acceptable level for China is currently the subject of heated debate. Some argue against setting a standard value for the whole country. If a standard value were to be set, however, 10 microtesla would seem to be an option. That would be fifty times the Swiss value - but at the same time only ten percent of the current Chinese value.

The necessary distance between the residential buildings and the Maglev railway is still unclear.

The construction costs of the Maglev light rail system will depend on the outcome of this discussion. The lower the value accepted by health policy, the more space will have to be left between the railway line and the nearest residential buildings.

This, however, may force extensive, expensive land purchases in order to be able to comply with the danger limit.

If, for example, the Swiss value were chosen in Changsha, 500 metres would have to remain undeveloped on each side of the railway line.

According to the current Chinese value, on the other hand, residential buildings can be built directly along the railway line.

Source: Imaginechina

E-mail: thalhammerm@yahoo.de - Tel: +43 1 9195724

See my video under Tubeway traffic :

https://www.youtube.com/watch?v=NuPNSNTFeUw

See also my video in: www.youtube.com/watch?v=19YDKukm2vc&t=18s

Pictures and 3D video - by Petrus Gartler, Graz - Designerei / 2003 Pexels and Pixabay